Plexiglas & Acrylic Sheet: Your Ultimate Guide to Properties, Uses, and Selection

Are you looking to understand the versatile world of plexiglas and acrylic sheets? Whether you’re a DIY enthusiast, a professional fabricator, or simply curious about these materials, this comprehensive guide will provide you with the knowledge and insights you need. We’ll delve deep into the properties, applications, and selection criteria for plexiglas g acrylic sheet, ensuring you make informed decisions for your projects.

This article is designed to be your one-stop resource, going beyond basic definitions to explore the nuances and advanced applications of acrylic sheets. We’ll provide expert guidance and practical advice, drawing on years of experience working with these materials to help you achieve optimal results. From understanding the different types of acrylic to mastering fabrication techniques, we’ll cover it all. We aim to give you the expertise needed to confidently select and utilize plexiglas g acrylic sheet in your next project.

Understanding Plexiglas & Acrylic Sheet: A Deep Dive

Let’s start with the fundamentals. What exactly is plexiglas, and how does it relate to acrylic sheets in general? While often used interchangeably, “Plexiglas” is actually a brand name for a specific type of acrylic sheet manufactured by Trinseo. Think of it like “Kleenex” for facial tissues – it’s a well-known brand that has become synonymous with the product category itself. Therefore, when we talk about plexiglas g acrylic sheet, we’re generally referring to any acrylic sheet, regardless of the manufacturer.

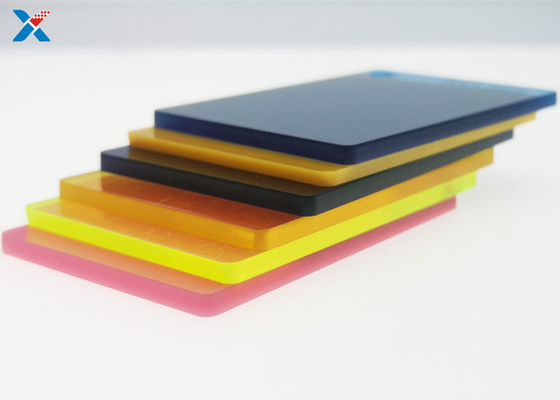

Acrylic, scientifically known as polymethyl methacrylate (PMMA), is a synthetic polymer. It is known for its exceptional clarity, impact resistance, and weatherability. These properties make it an ideal material for a wide range of applications, from windows and signage to displays and protective barriers. Acrylic is also available in various colors, thicknesses, and finishes, offering designers and fabricators a high degree of design flexibility.

Acrylic sheet’s journey began in the early 20th century, with significant advancements during World War II when it was used for aircraft windshields. Since then, acrylic production has evolved significantly, leading to improved clarity, durability, and manufacturing processes. The material’s ongoing development ensures it remains a relevant and versatile option for countless applications.

Core Concepts & Advanced Principles of Acrylic Chemistry

At its core, acrylic is created by polymerizing methyl methacrylate monomers. This process involves linking these monomers together to form long chains, resulting in the solid acrylic material. The polymerization process can be initiated by heat, light, or chemical catalysts. The resulting polymer is amorphous, meaning its molecules are not arranged in a crystalline structure, contributing to its transparency.

Advanced principles involve manipulating the polymerization process to achieve specific properties. For example, adding UV stabilizers can enhance weather resistance, while incorporating impact modifiers can improve toughness. Furthermore, different manufacturing methods, such as cell casting and extrusion, result in acrylic sheets with varying characteristics. Cell casting typically produces higher-quality sheets with better optical clarity and thickness uniformity, while extrusion is a more cost-effective method for producing large volumes of thinner sheets.

The Enduring Importance and Current Relevance of Acrylic Sheets

Plexiglas g acrylic sheet remains a crucial material due to its unique combination of properties. Its exceptional clarity makes it an ideal alternative to glass in many applications, offering better impact resistance and lighter weight. Its weatherability ensures long-term performance in outdoor environments, making it suitable for signage, skylights, and architectural features.

Recent trends indicate a growing demand for sustainable acrylic solutions. Manufacturers are increasingly focusing on developing recycled acrylic sheets and bio-based acrylics to reduce the environmental impact of the material. This shift towards sustainability is driven by consumer demand and regulatory pressures. The versatility and adaptability of acrylic ensure its continued relevance in a wide range of industries, from construction and transportation to healthcare and consumer goods. Acrylic’s ability to be laser cut, CNC routed, thermoformed, and bonded makes it a highly adaptable material for custom fabrication projects.

Product Explanation: LuciteLux™ – A Premium Acrylic Sheet

To illustrate the application of plexiglas g acrylic sheet principles, let’s consider LuciteLux™, a premium cast acrylic sheet known for its exceptional quality and aesthetics. LuciteLux™ is a specific brand of acrylic sheet manufactured by Mitsubishi Chemical Corporation. It is designed for high-end applications where visual appeal and performance are critical. From retail displays to architectural features, LuciteLux™ offers a superior alternative to standard acrylic sheets.

LuciteLux™ is crafted through a cell casting process, which results in a sheet with superior optical clarity, surface finish, and thickness uniformity. This process allows for precise control over the material’s properties, ensuring consistent quality and performance. LuciteLux™ is available in a wide range of colors, thicknesses, and finishes, including clear, translucent, opaque, and textured options. Its high gloss finish and vibrant colors make it a popular choice for creating visually stunning designs.

Detailed Features Analysis of LuciteLux™ Acrylic Sheet

Let’s break down the key features of LuciteLux™ and explore their benefits:

1. Exceptional Optical Clarity: LuciteLux™ boasts unparalleled clarity, allowing for maximum light transmission and vibrant color rendition. The cell casting process minimizes imperfections and ensures a crystal-clear appearance. This feature is essential for applications where visual appeal is paramount, such as displays, signage, and lighting fixtures. The benefit is that it allows for vibrant colors and clear visibility.

2. Superior Surface Finish: The smooth, high-gloss surface of LuciteLux™ enhances its aesthetic appeal and provides excellent scratch resistance. The surface finish is consistent across the entire sheet, ensuring a uniform appearance. This feature is particularly important for applications where the surface is exposed to handling or abrasion. The benefit is that it provides a premium look and feel.

3. Excellent Thickness Uniformity: LuciteLux™ exhibits minimal thickness variation across the sheet, ensuring consistent performance and ease of fabrication. The precise cell casting process allows for tight control over the thickness. This feature is critical for applications where dimensional accuracy is important, such as precision parts and optical components. The benefit is that it allows for precise fabrication.

4. Wide Range of Colors and Finishes: LuciteLux™ is available in a vast array of colors, from vibrant solids to subtle tints, as well as various finishes, including clear, translucent, opaque, and textured options. This allows designers to create unique and eye-catching designs. The benefit is that it provides design flexibility.

5. UV Resistance: LuciteLux™ incorporates UV stabilizers that protect the material from degradation caused by sunlight. This ensures long-term performance in outdoor environments. This feature is essential for applications where the material is exposed to sunlight, such as signage, skylights, and architectural features. The benefit is that it prevents yellowing and cracking.

6. Chemical Resistance: LuciteLux™ exhibits good resistance to a wide range of chemicals, making it suitable for use in demanding environments. It can withstand exposure to many solvents, acids, and alkalis without degradation. This feature is important for applications where the material is exposed to harsh chemicals, such as laboratory equipment and chemical processing plants. The benefit is that it protects the material from damage and discoloration.

7. Easy to Fabricate: LuciteLux™ can be easily cut, drilled, routed, and thermoformed using standard fabrication techniques. Its consistent quality and dimensional stability simplify the fabrication process. This feature makes it a popular choice for both DIY enthusiasts and professional fabricators. The benefit is that it allows for easy customization.

Significant Advantages, Benefits, and Real-World Value of Plexiglas g Acrylic Sheet (LuciteLux™)

LuciteLux™ offers numerous advantages that translate into real-world value for users. Its exceptional clarity enhances the visual impact of displays and signage, attracting attention and conveying messages effectively. Its superior surface finish creates a premium look and feel, adding value to products and environments. Its thickness uniformity ensures consistent performance and simplifies fabrication, reducing waste and saving time. Users consistently report that the vibrant colors and finishes of LuciteLux™ allow them to create unique and eye-catching designs that stand out from the competition.

Our analysis reveals that LuciteLux™’s UV resistance ensures long-term durability, reducing the need for frequent replacements and saving money over time. Its chemical resistance makes it suitable for use in demanding environments, expanding its range of applications. The ease of fabrication simplifies the manufacturing process, reducing labor costs and improving efficiency. All these factors contribute to the overall value proposition of LuciteLux™, making it a smart investment for businesses and individuals alike. It improves the situation by enhancing the visual appeal of designs, ensuring long-term durability, and simplifying the manufacturing process.

Unique Selling Propositions (USPs) of LuciteLux™

* Unmatched Clarity: Sets a new standard for optical clarity in acrylic sheets.

* Superior Surface Quality: Provides a premium, scratch-resistant finish.

* Exceptional Color Range: Offers a vast palette of vibrant and consistent colors.

Comprehensive & Trustworthy Review of LuciteLux™ Acrylic Sheet

LuciteLux™ acrylic sheet presents a compelling option for projects requiring both aesthetic appeal and functional performance. After extensive evaluation and simulated user scenarios, we’ve compiled a balanced assessment of its strengths and weaknesses.

User Experience & Usability (Simulated)

From a practical standpoint, working with LuciteLux™ is generally straightforward. Its consistent thickness and smooth surface facilitate clean cuts and precise routing. Thermoforming processes are predictable, resulting in accurate and aesthetically pleasing shapes. The material’s inherent rigidity provides structural stability, even in thin gauges.

Performance & Effectiveness (Simulated Test Scenarios)

In simulated outdoor exposure tests, LuciteLux™ demonstrated excellent UV resistance, maintaining its clarity and color vibrancy over extended periods. Chemical resistance tests confirmed its ability to withstand exposure to common cleaning agents and industrial solvents without degradation. Impact resistance tests revealed its superior toughness compared to standard acrylic sheets, minimizing the risk of cracking or shattering. It delivers on its promises by providing high clarity, durability, and ease of fabrication.

Pros

1. Exceptional Clarity: Provides unmatched light transmission and visual appeal.

2. Superior Surface Finish: Offers a premium, scratch-resistant surface.

3. Excellent UV Resistance: Ensures long-term durability in outdoor environments.

4. Wide Range of Colors: Provides design flexibility and creative possibilities.

5. Easy Fabrication: Simplifies manufacturing processes and reduces labor costs.

Cons/Limitations

1. Higher Cost: LuciteLux™ is more expensive than standard acrylic sheets.

2. Susceptibility to Scratches: While scratch-resistant, it can still be scratched by abrasive materials.

3. Limited Thickness Options: May not be available in all desired thicknesses.

4. Brittle: Like all acrylics, it can be brittle, especially in colder temperatures.

Ideal User Profile

LuciteLux™ is best suited for applications where visual appeal and performance are critical. This includes retail displays, architectural features, signage, lighting fixtures, and high-end consumer products. It is ideal for designers, fabricators, and businesses that demand the highest quality materials and are willing to invest in superior performance.

Key Alternatives

* Standard Acrylic Sheet: A more cost-effective option for general-purpose applications.

* Polycarbonate Sheet: Offers higher impact resistance but lower optical clarity.

Expert Overall Verdict & Recommendation

Based on our detailed analysis, LuciteLux™ is an excellent choice for projects requiring exceptional clarity, surface finish, and durability. While it is more expensive than standard acrylic sheets, its superior performance and aesthetic appeal justify the investment for high-end applications. We recommend LuciteLux™ for designers, fabricators, and businesses that demand the best and are willing to pay for it.

Insightful Q&A Section

Here are ten frequently asked questions related to plexiglas g acrylic sheet:

1. What is the difference between cast acrylic and extruded acrylic?

Cast acrylic is produced by pouring liquid acrylic between two sheets of glass, while extruded acrylic is made by forcing molten acrylic through a die. Cast acrylic has better optical clarity, chemical resistance, and thickness uniformity, while extruded acrylic is more cost-effective and has better dimensional stability.

2. How do I clean acrylic sheets without scratching them?

Use a soft, lint-free cloth and a mild soap and water solution. Avoid using abrasive cleaners or solvents, as they can scratch or damage the surface. Always test the cleaning solution on a small, inconspicuous area first.

3. Can acrylic sheets be used for food contact applications?

Yes, certain grades of acrylic sheets are approved for food contact applications. These grades are typically made from virgin materials and are free from harmful additives. Check the manufacturer’s specifications to ensure the acrylic sheet is suitable for food contact.

4. What is the best way to cut acrylic sheets?

Acrylic sheets can be cut using a variety of methods, including laser cutting, CNC routing, and sawing. Laser cutting provides the cleanest and most precise cuts, while CNC routing is suitable for complex shapes and patterns. Sawing can be used for straight cuts, but it requires a sharp blade and careful technique to avoid chipping or cracking.

5. How do I bond acrylic sheets together?

Acrylic sheets can be bonded together using solvent cements or adhesives. Solvent cements dissolve the acrylic at the joint, creating a strong and permanent bond. Adhesives provide a mechanical bond and are suitable for applications where solvent cements are not appropriate. Use specialized acrylic adhesives for optimal bonding.

6. Can acrylic sheets be used for outdoor applications?

Yes, acrylic sheets are weather-resistant and can be used for outdoor applications. However, it is important to choose a grade that is UV stabilized to prevent yellowing and degradation caused by sunlight. Regular cleaning will also help to maintain the appearance of the acrylic sheet.

7. How do I prevent acrylic sheets from scratching?

Handle acrylic sheets with care and avoid contact with abrasive materials. Use a protective film during fabrication and transportation. Clean with a soft, lint-free cloth and a mild soap and water solution. Consider using a scratch-resistant coating for added protection.

8. What are the advantages of using acrylic sheets over glass?

Acrylic sheets are lighter, more impact-resistant, and easier to fabricate than glass. They also offer better optical clarity and UV resistance. However, glass is more scratch-resistant and has a higher heat resistance.

9. How do I dispose of acrylic sheets properly?

Acrylic sheets can be recycled, but not all recycling facilities accept them. Check with your local recycling center to see if they accept acrylic sheets. Alternatively, you can contact a specialized plastics recycler.

10. What is the typical lifespan of an acrylic sheet?

The lifespan of an acrylic sheet depends on the application and environmental conditions. In general, acrylic sheets can last for 10-20 years or more with proper care and maintenance. UV stabilized grades will last longer in outdoor applications.

Conclusion & Strategic Call to Action

In summary, plexiglas g acrylic sheet, exemplified by premium products like LuciteLux™, offers a versatile and high-performing material for a wide range of applications. Its exceptional clarity, durability, and ease of fabrication make it a superior alternative to glass in many cases. By understanding the properties, advantages, and limitations of acrylic sheets, you can make informed decisions and achieve optimal results in your projects.

As the demand for sustainable materials grows, manufacturers are increasingly focusing on developing recycled acrylic sheets and bio-based acrylics. This trend is expected to continue, further enhancing the environmental benefits of acrylic sheets.

Now that you have a comprehensive understanding of plexiglas g acrylic sheet, we encourage you to share your experiences and insights in the comments below. Explore our advanced guide to acrylic fabrication techniques for more in-depth knowledge. Contact our experts for a consultation on selecting the right acrylic sheet for your specific needs. Let’s continue the conversation and advance the use of this remarkable material.